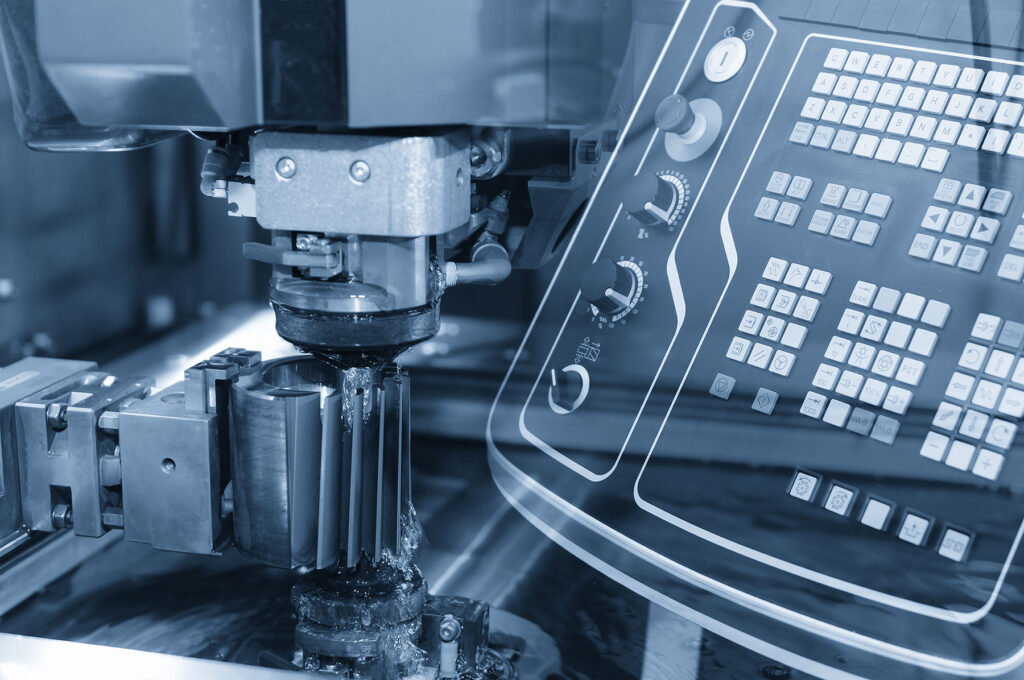

Ballco Manufacturing Co Inc., founded in 1988, is an industrial machinery equipment manufacturer based in Aurora, Illinois, United States. The company specializes in producing precision machined components for various industries, including OEM valves, rail car components, aerospace components, and defense & military components. Its product line includes valve balls, gland flanges & plates, valve end connects, flange bodies, check valve bodies, etc. It manufactures precision parts according to AS9100D standards, which are aerospace and defense standards, and is also ISO 9001:2015 certified. Ballco also offers warehousing and distribution programs to meet their customers’ needs.

About

Ballco Manufacturing Inc

Has been a leading provider of precision machined components for the valve industry since 1988.

They offer a wide range of products, including ball valves, bodies, check valves, and various other machined components.